Steam Fracking™

Back Ground

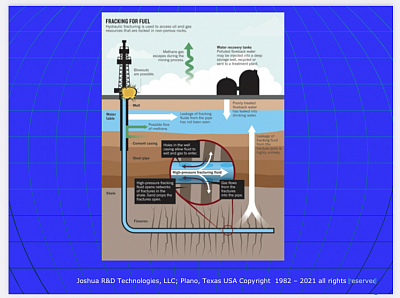

Fracking is shorthand for hydraulic fracturing, a type of petroleum well completion that has been used commercially for 65 years. Today, the combination of advanced mechanical pump hydraulic fracturing and horizontal drilling, employing cutting-edge technologies, is mostly responsible for surging U.S. oil and natural gas production.

Problem

Currently, hydraulic water pump fracking is expensive, making payback lengthy, and making smaller well production not cost effective. Hydraulic water pump fracking is dangerous, adding to operating costs of insurance, etc. The hydraulic water pump process must be repeated numerous times with lengthy delays for mechanical pumps to build up the hydraulic pressure needed to frack.

Solution = STEAM FRACKING:

The invention’s high energy spark initiator is maneuvered into the horizontal drill hole where a petroleum bearing formation needs to be fractured in order for the petroleum trapped in the formation to flow out through these cracks and into the horizontal borehole, where it is pumped / flows up hole to the surface for collection.

The horizontal borehole is flooded with “fracking water” (water and sand) (slickwater) which submerges the spark initiator.

A high energy electric charge is sent to the spark initiator in the range of a 100,000+ to 1 MM joules

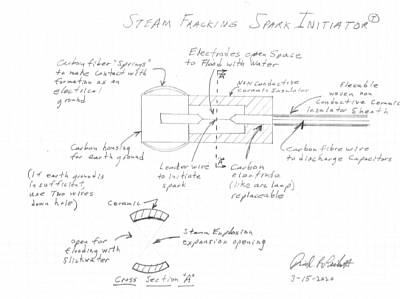

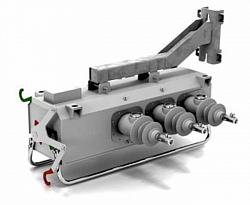

The voltage is sparked across the positive and negative contacts on the spark initiator (like a spark plug); DRAWING PAGE 8, followed by a high energy steam explosion, caused by the near-plasma heat of the initiator spark, which heats the water in the borehole near the initiator into very high pressure live steam.

The live steam expands 1,700 times the weight / volume of the water. The water near the spark is converted to steam at up to 17,000+ PSI almost instantaneously. Twice the pressure in a shotgun barrel. Traditional fracking is 9,000 PSI.

This sharp steam explosion gas bubble instantaneously expands and pushes against the remaining horizontal column of liquid water / sand in the borehole that was not converted to steam.

This large force against the horizontal column of incompressible water will exert a very high instantaneous hydraulic force against the formations along the horizontal bore hole.

The very high pressure impulse from the steam explosion creates a hydraulic pressure along the entire column of water in the horizontal borehole containing the water /sand.

Since water is not compressible, the entire instantaneous 17,000 PSI hydraulic impulse is transmitted evenly along the horizontal column of water, where the extreme hydraulic impulse force will cause small fractures in the formation to “spread open”, and the water/sand will be forced to jet into the fractures and will be compacted into the formation cracks at the high pressure impulse to “hold the cracks open” so the petroleum or gas it contains will flow out later.

This extreme hydraulic impulse pressure on the walls of the entire length of the horizontal borehole will crack the rock formation to a depth and extent proportional to the hydraulic pressure caused by the steam explosion’s energy.

The relationship of the amount of hydraulic pressure and the extent of the formation cracking is well known from conventional hydraulic water pump fracking.

Consider that an ‘instantaneous’ hydraulic impulse will tend to crack formation walls instead of slowly ‘opening’ or ‘spreading’ cracks with the slow build up of truck pump pressure fracking.

The depth and extent of instantaneous pressure impulse will greatly exceed the slow build up of a hydraulic pump.

PROBLEM:

THE EXTREME HEAT OF THE SPARK AT THE ELECTRODES OF THE SPARK INITIATOR WILL MELT THE METAL OF THE ELECTRODES.

AND THE VERY HIGH CURRENT IN THE WIRE RUNNING FROM THE SPARK INITIATOR’S ELECTRODES TO THE SURFACE ENERGY SOURCE WILL MELT THE WIRE.

SOLUTION:

THE SPARK INITIATOR IS MADE FROM HIGH TEMPERATURE CONDUCTIVE AND INSULATING CERAMIC AND CARBON (like an arc lamp)

THE WIRE FROM THE SPARK INITIATOR ELECTRODE TO THE POWER SOURCE IS MAKE OF CARBON FIBER WITH A WOVEN CERAMIC INSULATION SHEATH.

PROBLEM:

PORTABLE GENERATORS CAPABLE OF A 100,000+ JOULES OF ENERGY ARE PROHIBITIVELY

EXPENSIVE

SOLUTION:

COMMERCIALLY AVAILABLE DC GENERATOR(S) WILL CHARGE UP A CAPACITOR BANK TO STORE ENOUGH ENERGY NEEDED FOR THE STEAM EXPLOSION SPARK.

CAPACITORS NEEDED CAN BE (used) STANDARD CAPACITORS AVAILABLE TO THE ELECTRIC POWER TRANSMISSION AND GENERATOR INDUSTRY, OR THE NEW “SUPER CAPACITORS” WHICH ARE MORE EXPENSIVE BUT OFFER ADVANTAGES IN SIZE AND DISCHARGE RATE.

THE LARGE SWITCHES NEEDED TO CONNECT THE CAPACITORS TO THE WIRE GOING DOWN HOLE TO THE SPARK INITIATOR CAN BE STANDARD SWITCHES AVAILABLE TO THE ELECTRIC POWER TRANSMISSION AND GENERATOR INDUSTRY.

THESE STANDARD SWITCHES MUST BE FITTED WITH CARBON CONTACTORS TO PREVENT MELTING WITH EACH DISCHARGE.

SAFETY:

The massive steam explosion impulse will create hydraulic water pressure up the vertical borehole to the well as far as the water (mud) column continues to carry the hydraulic pressure.

Such extreme instantaneous impulse hydraulic pressure to the well head would have devastating damage to the wellhead, rig and personnel.

By having no water (mud) column for some distance above the vertical borehole fluid level, there will be no hydraulic pressure extended up the borehole.

A column of air acts like a shock absorber between the vertical hydraulic column of drilling mud and the surface.

The down hole hydraulic pressure impulse will meet the up hole air column and the hydraulic pressured surge will be absorbed by the compressible air column. The pressurized air will merely be a controlled bleed off. To capture / ‘recycle’ the energy, the pressured bleed air can turn a generator to charge the capacitors.

A great advantage of this method is that the process can be repeated*** with measured steam explosions as fast as the capacitor bank can cycle / charge up.

Electricity from neighboring transmission lines can be used instead of or to supplement commercial portable generators.

***the process may be repeated numerous times in quick succession because the electrodes and spark initiator itself and the power wire and the switch contacts are not melted with each discharge.

The extent / depth of the hydraulic formation fracking (fracturing) is controlled by adjusting the total power charge of the capacitor bank that is sent to the spark initiator which will control the size of the spark and the resulting steam explosion pressures.

The science here is that the energy from (for example) 1,000 horsepower pumps for 10 minutes could have been stored in capacitors and released as an instantaneous (1 /1000th of a second) spark resulting in 36,000,000,000 (BILLION) impulse horsepower of hydraulic fracking pressure for the steam explosion.

The science is that the energy generated over 10 minutes by a 1,000 HP generator can instead be stored and discharged in 1/1000 of a second, greatly compounding the hydraulic pressure on the formation by a factor of 3,600,000*

*less the energy lost as heat and resistance, loss in steam propagation, loss over the length of the (carbon fiber ceramic fabric insulated) wire and losses to the earth ground between the spark initiator and the capacitor switch.

*No special high pressure pumps, just commercially available portable DC generators.

*Capacitors and switches are commercially available (used) power transmission equipment.

*Carbon - ceramic spark initiators are easily built in machine shops Carbon fiber wire is available

SAFETY:

No dangerous high pressure pumps

No dangerous high pressure pipes, tubing or hoses.

No unpredictable high pressure running down the expensive well borehole which may cause collapse or other damage.

SAFETY:

No dangerous high pressure build up running down the expensive well borehole which may cause collapse or other damage, destroying the hole.

No expensive special high pressure well tubing needed.

Uses standard slickwater fracking chemicals.

Inexpensive generators uses less fuel than expensive hydraulic high pressure pump trucks.

Cost per completed fracking project is less expensive and faster.

May be possible to frack formations that are now not possible to frack due to limitations of mechanical pump pressure.

Greatly reduced fracking costs can make it possible to frack lesser wells where the payback was previously not feasible or payback too long or budgets too small.

Possibly economic feasibility for opening up non producing wells.

May make fracking legal in areas where fracking is not legal due to water pollution, etc.

No noisy high pressure pumps running for hours; just relatively quiet generators (no generators needed where local electric lines are nearby.)

Cost for a live-site demonstration would be reasonable.

No new technology to invent.

Fabricating the initiator and sourcing the carbon fiber power wire are doable.

Cost is reasonable for a small scale proof of concept demonstration:

Assemble a long tubing section, closed at both ends, insert a small scale carbon and ceramic spark initiator and fill with slickwater.

Send a large measured instantaneous electrical charge from a capacitor bank to the spark initiator.

Measure the hydraulic pressure from the steam explosion vs. the electric power used.

Extrapolate these pressures to known mechanical pump fracking pressure tables and compare the fuel used and cycle time between fracks, to establish cost savings.

Additional small scale demonstration savings:

From the small scale demonstration, extrapolate the cost savings of not using high pressure mechanical pumps, tubing or valves, the labor associated with these, and the cost of money thereof.

Extrapolate the total project timeline period of steam fracking vs. mechanical pump fracking.

Timely grants may be available for the demonstration:

Possible funding from fracking companies, oil companies or service companies interested in first right of refusal for exclusive licensing of the patent.

Grants from DOE and other government agencies are possible but can take years to get.

University participation lends very necessary credibility, but they expect large day fees for testing. (so hire independent contractor testing with University on-site auditing.)

University royalties from the resulting patent are reasonable. Industry is constantly courting Universities for emerging technologies.

Licensing should be on a country by country basis to increasing licensing revenues.

Or region by region.

Next step; get started…

Contact us: